EDX-8100

The Energy Dispersive X-ray Fluorescence spectroscopy (ED-XRF) is a non-destructive analytical technique for identifying and quantifying elemental compositions in solid, powder, and liquid samples. It is widely used for non-destructive elemental analysis for quality and process control in applications including metals, chemicals, polymers, environmental testing, food safety, and pharmaceuticals, etc. The EDX-8100 energy dispersive X-ray fluorescence spectrometer offers a high level of accuracy and speed in analyzing elements contained in various samples. It supports ultra-light element analysis of 6C to 92U, and can be used in conjunction with the helium substitution option to analyze liquid samples containing light elements (F to Al) as is.EDX-8100: One EDX over all others

Product Description

The Energy Dispersive X-ray Fluorescence spectroscopy (ED-XRF) is a non-destructive analytical technique for identifying and quantifying elemental compositions in solid, powder, and liquid samples. It is widely used for non-destructive elemental analysis for quality and process control in applications including metals, chemicals, polymers, environmental testing, food safety, and pharmaceuticals, etc. The EDX-8100 energy dispersive X-ray fluorescence spectrometer offers a high level of accuracy and speed in analyzing elements contained in various samples. It supports ultra-light element analysis of 6C to 92U, and can be used in conjunction with the helium substitution option to analyze liquid samples containing light elements (F to Al) as is.EDX-8100: One EDX over all others

Technical specifications

Supports Various Applications in Many Fields

- ■ Electrical/electronic materials

-

- RoHS and halogen screening

- Thin-film analysis for semiconductors, discs, liquid crystals, and solar cells

- ■ Automobiles and machinery

-

- ELV hazardous element screening

- Composition analysis, plating thickness measurement, and chemical conversion coating film weight measurement for machine parts

- ■ Ferrous/non-ferrous metals

-

- Main component analysis and impurity analysis of raw materials, alloys, solder, and precious metals

- Composition analysis of slag

- ■ Mining

-

- Grade analysis for mineral processing

- ■ Ceramics

-

- Analysis of ceramics, cement, glass, bricks, and clay

- ■ Oil and petrochemicals

-

- Analysis of sulfur in oil

- Analysis of additive elements and mixed elements in lubricating oil

- ■ Chemicals

-

- Analysis of products and organic/inorganic raw materials

- Analysis of catalysts, pigments, paints, rubber, and plastics

- ■ Environment

-

- Analysis of soil, effluent, combustion ash, filters, and fine particulate matter

- ■ Pharmaceuticals

-

- Analysis of residual catalyst during synthesis

- Analysis of impurities and foreign matter in active pharmaceutical ingredients

- ■ Agriculture and foods

-

- Analysis of soil, fertilizer, and plants

- Analysis of raw ingredients, control of added elements, and analysis of foreign matter in foods

- ■ Other

-

- Composition analysis of archeological samples and precious stones, analysis of toxic heavy metals in toys and everyday goods

PCEDX Navi Software Allows Easy Operation from the Start

Unrivaled Analytical Performance

The high-performance SDD detector and optimized hardware achieve a high level of sensitivity, analysis speed, and energy resolution that were previously unattainable. It supports light element analysis of 6C to, and can be used in conjunction with the helium substitution option to analyze liquid samples containing light elements (F to Al) as is.

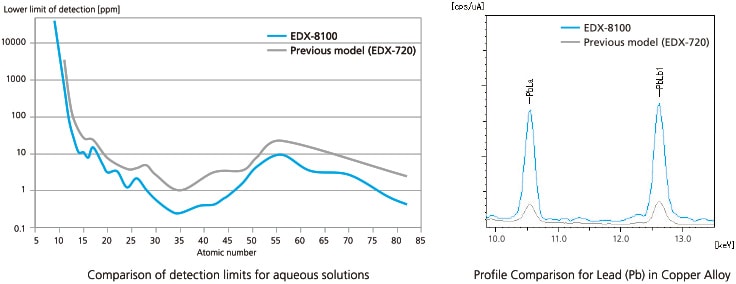

High Sensitivity − Lower Limit of Detection Improved 1.5 to 5 Times! −

The high-performance SDD detector and combination of optimized optics and primary filters achieve previously unheard-of high levels of sensitivity. The sensitivity is higher than the previous Si (Li) semiconductor detector across the entire range from light to heavy elements.

High Speed − Throughput Increased by up to a Factor of 10 −

The high fluorescent X-ray count per unit time (high count rate) of the SDD detector permits highly precise analysis in a shorter measurement time. This feature is achieved to the maximum when analyzing samples that generate a lot of fluorescent X-rays, such as samples with a metal as the Main component element.

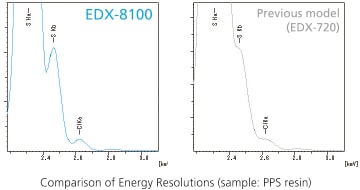

High Resolution

The EDX-8100 instruments achieve superior energy resolution compared to previous models by incorporating a state-of-the-art SDD detector.

No Liquid Nitrogen Required

Ultra-Light Element Analysis by EDX-8100

The EDX-8100 features an SDD detector with a special ultra-thin-film window material that is able to detect ultra-light elements such as carbon (C), oxygen (O), and fluorine (F)

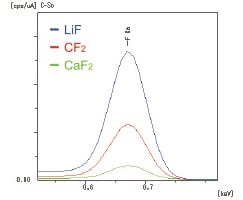

Freely Combine Collimators and Primary Filters

Optional Vacuum Measurement Unit and Helium Purge Unit

Advanced Helium Purge Unit (Option)

Comprehensive Quantitation Functions

Calibration Curve Method

A standard sample is measured and the relationship with the fluorescent X-ray intensity plotted as a calibration curve, which is used for the quantitation of unknown samples.